Have you ever wondered how modern vehicles maintain their course, recognize potential obstacles, and deliver such a smooth driving experience? The secret lies in Advanced Driver Assistance Systems (ADAS) and their critical need for precise calibration. In this article, we’ll discuss the role of calibration in ADAS, emphasizing why it’s essential for both accuracy and safety.

This image is property of fivestarautocentre.co.uk.

In need of auto care? Dial 913-605-3126 for remote or in-shop services!

What is ADAS?

ADAS, or Advanced Driver Assistance Systems, represents a suite of electronic technologies in vehicles designed to assist drivers in driving and parking functions. ADAS systems rely on a variety of sensors, cameras, radar, and other data sources to make driving safer and easier.

Core Components of ADAS

A wide range of components make up ADAS, including:

| Component | Function |

|---|---|

| Cameras | Monitor surroundings and detect objects, lanes, and traffic signals. |

| Radar | Measures distance and speed of objects to avoid collisions. |

| Lidar | Uses lasers to create detailed 3D maps of the vehicle’s environment. |

| Ultrasonic Sensors | Aid in parking by detecting obstacles nearby. |

| GPS | Provides precise location data to support navigation and other functions. |

These components are integrated into systems such as adaptive cruise control, lane-keeping assistance, parking assist, and collision avoidance, among others.

Importance of Calibration

Calibration ensures the sensors and systems of ADAS work together harmoniously, delivering accurate readings and responses. Without proper calibration, even the most advanced systems can produce inaccuracies that compromise both performance and safety.

Accuracy in Sensing and Interpretation

Sensors are the eyes and ears of ADAS. If a sensor is misaligned, it could misinterpret data, leading to incorrect decisions by the system. For instance, a misaligned camera may fail to recognize lane markings accurately, resulting in ineffective lane-keeping assistance.

Safety: The Non-negotiable Factor

Safety is at the heart of all ADAS functionalities. Calibration directly affects the reliability of safety features. Whether it’s automatic emergency braking or blind-spot detection, the efficacy of these features is contingent on proper calibration.

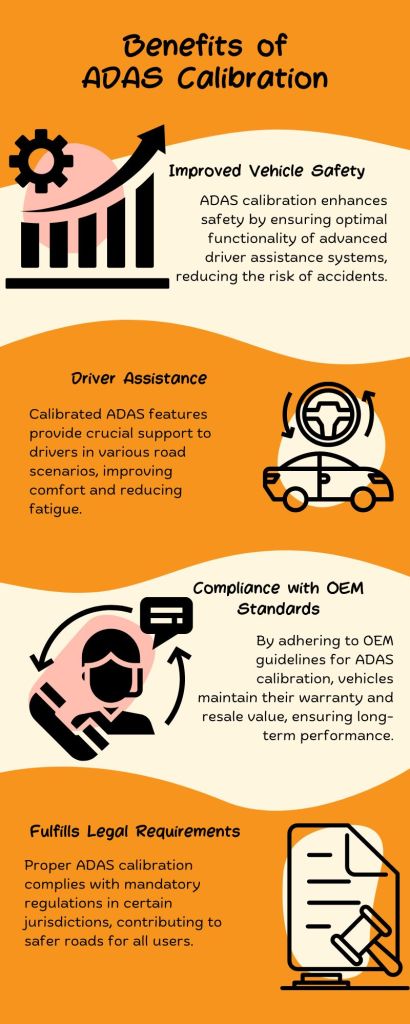

This image is property of i0.wp.com.

How Calibration Works

Calibration involves adjusting the ADAS sensors to ensure they can accurately interpret the real world. It’s a multi-step process that often requires specialized equipment and software.

Initial Calibration

The initial calibration happens during the manufacturing process. Each sensor is aligned and tuned to meet the precise specifications of the vehicle model. This sets a baseline for future calibrations.

Dynamic and Static Calibration

There are two primary types of calibration: dynamic and static.

- Dynamic Calibration: This type takes place while the vehicle is in motion. The ADAS system gathers data from real-world conditions and adjusts the sensors accordingly.

- Static Calibration: Performed while the vehicle is stationary, usually in a workshop. Specific targets and tools are used to align the sensors.

| Calibration Type | Description | When Used |

|---|---|---|

| Dynamic | Calibration while the vehicle is moving | Adjusting sensors to real-world conditions |

| Static | Calibration while the vehicle is stationary | Uses targets/tools, often done in workshops |

Recalibration

Recalibration is necessary after certain events, such as:

- Windshield Replacement: Many ADAS sensors are mounted on or near the windshield.

- Collision or Impact: An accident can throw sensors out of alignment.

- Suspension Changes: Altering the vehicle’s height can affect sensor alignment.

- Software Updates: Upgrades or changes in ADAS software may require recalibration.

The Calibration Process: Step by Step

Let’s break down the general steps for a typical calibration, whether it’s initial, dynamic, or static.

Step 1: Pre-Calibration Checks

Before starting the calibration, technicians often perform checks to ensure that the vehicle’s sensors are clean and undamaged. They also verify that the vehicle is on a level surface, and any diagnostic trouble codes need to be addressed.

Step 2: Using OEM Specifications

Each vehicle manufacturer provides specific guidelines for calibrating ADAS sensors. Technicians consult these OEM (Original Equipment Manufacturer) specifications to understand the precise requirements.

Step 3: Setting Up Calibration Equipment

For static calibration, this involves setting up targets and measurement tools around the vehicle. Dynamic calibration might require tools that connect to the car’s OBD-II port to monitor sensor data as the car moves.

Step 4: Calibration Procedure

During the calibration, the ADAS system is guided through a series of steps to align and validate sensor accuracy. This might involve driving the vehicle under specific conditions or adjusting targets until the sensors are correctly aligned.

Step 5: Post-Calibration Verification

Technicians perform tests to verify that the calibration was successful. This usually includes test drives to ensure that the ADAS functions are operating accurately and within the specified parameters.

This image is property of a-us.storyblok.com.

Why DIY Calibration Isn’t an Option

While it might be tempting to consider DIY approaches for other car maintenance tasks, ADAS calibration is far too complex and critical to safety. The specialized equipment, software, and expertise required make it a job best left to professionals.

Risks of Improper Calibration

Improper calibration can lead to various problems:

- False Positives or Negatives: Sensors may incorrectly detect objects or fail to detect them at all.

- Compromised Safety: Safety features may fail to activate when needed.

- Vehicle Damage: Incorrectly performed calibration can damage the vehicle’s ADAS components.

Future Trends in ADAS Calibration

The field of ADAS is rapidly evolving, and with it, the methods and technologies for calibration are also advancing.

Automation and AI Integration

Incorporating Artificial Intelligence (AI) could revolutionize the calibration process, making it more efficient and accurate. AI algorithms can adapt calibration settings based on real-time data, reducing the need for manual intervention.

Increased Sensor Integration

Future vehicles will likely employ an even larger array of sensors, each requiring meticulous calibration. The interdependence of these sensors will necessitate even more sophisticated calibration techniques.

Connectivity and Over-the-Air Updates

With advancements in vehicle connectivity, over-the-air (OTA) updates can play a significant role in calibration. Manufacturers can push updates directly to vehicles, adjusting sensor calibrations remotely.

This image is property of toyotech.com.au.

Conclusion

The meticulous calibration of ADAS systems is indispensable for ensuring both accuracy and safety. From initial calibration during manufacturing to recalibrations after specific events, each step in the process is crucial for the reliable operation of driver-assist features. Given the complexity and importance of proper calibration, it’s a task best left to professionals equipped with the right tools and expertise.

By understanding the role of calibration in ADAS, you can better appreciate the sophisticated technology that goes into modern vehicles and the importance of maintaining it correctly. The future promises even more advancements, making calibration an ever-evolving and vital component of automotive safety and functionality.

Need auto care? Call 913 605-3126 for remote or in-shop services!